Introduction

In the fast-paced world of electronics manufacturing, efficiency and reliability are paramount. One stop PCB assembly provides a streamlined solution that simplifies the entire process, allowing businesses to focus on innovation rather than logistics. By integrating multiple services under one roof, manufacturers can significantly enhance their productivity and reduce unnecessary complexities.

Benefits of One Stop PCB Assembly

One stop PCB assembly offers numerous benefits that can elevate your project from concept to reality with remarkable ease. With access to a comprehensive range of services—from design to manufacturing—companies can save valuable time and resources while ensuring high-quality results. Additionally, working with one stop PCB assembly manufacturers fosters better communication and collaboration throughout the production cycle, leading to fewer errors and faster turnaround times.

Convenience of Integrated Services

The convenience offered by integrated services cannot be overstated; it simplifies the entire supply chain process into a cohesive workflow. When you choose one stop PCB assembly parts, you eliminate the hassle of coordinating multiple vendors, allowing for smoother operations and less room for miscommunication. This level of convenience translates into an overall more efficient project management experience, making it easier for teams to stay focused on their core objectives.

Cost-Effectiveness in Projects

Cost-effectiveness is a crucial consideration in any electronics project, and one stop PCB assembly excels in this area as well. By consolidating various services into a single package, businesses can enjoy significant savings on both time and costs associated with procurement and logistics. Moreover, when searching for PCB assembly services near me, opting for integrated solutions often leads to competitive pricing without sacrificing quality—making it an attractive choice for companies looking to maximize their budgets.

What is One Stop PCB Assembly?

One Stop PCB Assembly is a comprehensive service that simplifies the entire process of printed circuit board manufacturing and assembly. This integrated approach combines various stages, from design to final assembly, ensuring that clients receive a complete solution tailored to their specific needs. By utilizing One Stop PCB Assembly, businesses can streamline operations and enhance efficiency in their electronic projects.

Definition and Overview

At its core, One Stop PCB Assembly refers to a service model where multiple aspects of PCB production are handled under one roof. This includes everything from sourcing materials to assembling the final product, making it an attractive option for companies looking for convenience and reliability. With a focus on efficiency, this approach reduces the need for multiple vendors and simplifies communication throughout the process.

Key Components of the Service

The key components of One Stop PCB Assembly include design assistance, material procurement, manufacturing processes such as SMT (Surface Mount Technology), and thorough testing before delivery. Each element plays a crucial role in ensuring that the final product meets quality standards while adhering to project timelines. Additionally, many One Stop PCB Assembly manufacturers provide value-added services like prototyping and after-sales support, further enhancing their offerings.

Importance in Electronics Manufacturing

In today's fast-paced electronics industry, time-to-market can be critical for success; hence, One Stop PCB Assembly has become increasingly important. By consolidating various processes into one service provider, companies can significantly reduce lead times while maintaining high-quality standards. Moreover, this approach fosters better collaboration among teams involved in different stages of development—ultimately leading to innovative solutions that meet market demands effectively.

The Role of Bensun Technology

Bensun Technology stands out in the competitive landscape of electronics manufacturing by offering a robust suite of one stop PCB assembly solutions. Their commitment to providing integrated services ensures that clients can efficiently manage their projects from start to finish. With a focus on quality and adaptability, Bensun is a go-to choice for those seeking reliable PCB assembly services near me.

Comprehensive Solutions Offered

At Bensun Technology, the emphasis on comprehensive solutions means that customers receive everything they need under one roof for their one stop PCB assembly needs. From design and prototyping to full-scale production, they cover all aspects of PCB assembly, including sourcing high-quality components and managing logistics. This holistic approach not only simplifies the process but also enhances communication and coordination throughout the project lifecycle.

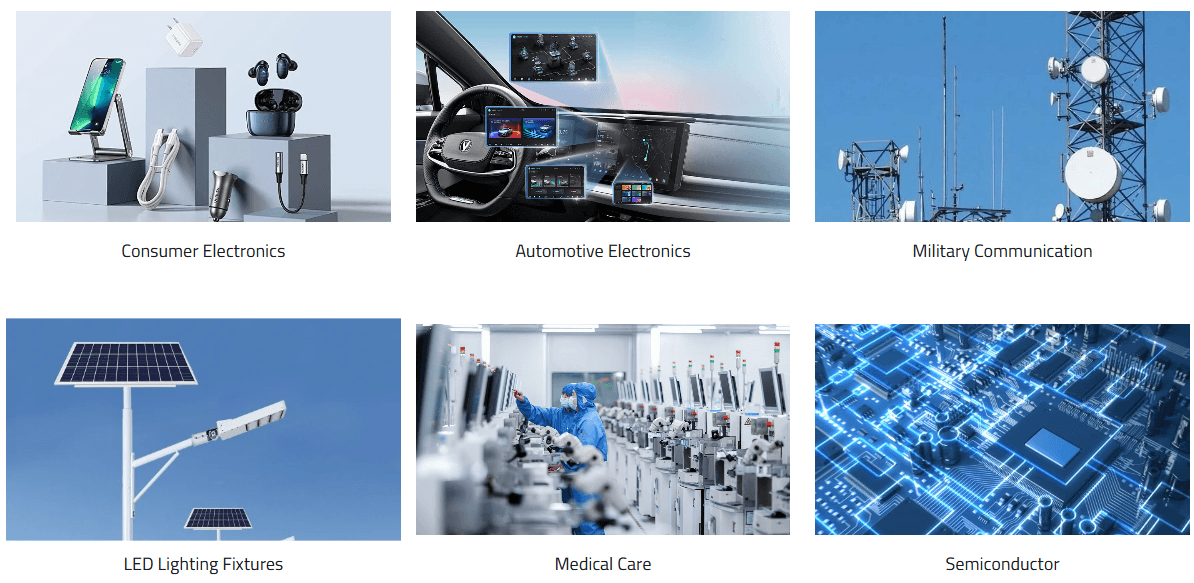

Adaptable Services for Various Needs

One size does not fit all in the world of electronics manufacturing, which is why Bensun offers adaptable services tailored to meet diverse client requirements. Whether you're looking for specialized one stop PCB assembly parts or custom configurations for unique projects, their flexible offerings can accommodate various demands. This adaptability extends beyond just product specifications; it also includes project timelines and budget considerations, allowing clients to find the perfect balance between quality and cost-effectiveness.

Quality Assurance in PCB Assembly

Quality assurance is at the heart of Bensun Technology’s operations, ensuring that every unit produced meets stringent industry standards. Utilizing advanced SMT PCB assembly service techniques, they guarantee superior efficiency and precision in every project they undertake. Clients can rest easy knowing that rigorous testing protocols are in place to catch any potential issues before products reach the market, further solidifying Bensun’s reputation as a trusted partner among one stop PCB assembly manufacturers.

Advantages of Using One Stop PCB Assembly Parts

When it comes to electronics manufacturing, utilizing one stop PCB assembly parts can significantly enhance the overall efficiency and effectiveness of your projects. By consolidating various processes under one roof, companies can enjoy a multitude of benefits that streamline operations and improve outcomes. Let's delve into some of the key advantages that make these services an attractive choice for businesses looking to optimize their PCB assembly.

Streamlined Supply Chain

One of the standout benefits of using one stop PCB assembly is the streamlined supply chain it offers. By integrating multiple services—such as design, prototyping, and production—under one umbrella, manufacturers can eliminate unnecessary delays and complexities associated with juggling different suppliers. This not only simplifies logistics but also ensures that all components are compatible and ready for immediate use in your project.

Furthermore, working with one stop PCB assembly manufacturers means you have a single point of contact for your entire project. This fosters better communication and coordination among teams, reducing the chances of miscommunication that often arise when dealing with multiple vendors. In essence, a streamlined supply chain leads to smoother operations and ultimately saves time and resources.

Reduced Lead Times

Another compelling advantage is the reduction in lead times associated with one stop PCB assembly services. When all aspects of the production process are handled by a single provider, there’s less waiting around for parts or information from various sources. This allows for quicker turnaround times on projects, which is crucial in today’s fast-paced market where speed often translates to competitive advantage.

Moreover, reduced lead times mean you can respond more rapidly to changes in demand or market conditions without being bogged down by lengthy procurement processes. For businesses looking to stay agile and innovative, this flexibility is invaluable. With faster delivery schedules facilitated by efficient online PCB manufacturing options, you can keep your projects on track without compromising quality.

Enhanced Project Collaboration

Utilizing one stop PCB assembly parts also enhances project collaboration among team members involved in electronics development. When everyone works within a unified framework provided by dedicated PCB assembly services near me, there’s greater alignment on goals and expectations throughout each stage of production. This collaborative environment fosters creativity as team members can easily share ideas and feedback without barriers created by disparate systems or suppliers.

Additionally, enhanced collaboration leads to improved problem-solving capabilities; issues can be addressed more quickly when everyone is on the same page regarding timelines and specifications. The synergy created through integrated services not only boosts morale but also drives innovation as teams work together towards common objectives with greater clarity and purpose. Ultimately, this collaborative spirit cultivates successful partnerships between clients and service providers alike.

Finding Reliable PCB Assembly Services Near Me

In the quest for reliable PCB assembly services near me, it’s essential to know how to sift through the options available. The right provider can significantly impact your project's success, ensuring quality and efficiency in production. Here’s a guide to help you find top-notch one stop PCB assembly solutions tailored to your needs.

How to Identify Quality Providers

Identifying quality providers for one stop PCB assembly involves several key factors. Start by checking online reviews and testimonials from previous clients; these insights can reveal a lot about the reliability and service quality of potential manufacturers. Additionally, consider their experience with SMT PCB assembly services, as this technology often signifies advanced capabilities in precision and efficiency.

Another way to gauge a provider's credibility is by asking for case studies or examples of past projects involving one stop PCB assembly parts. This not only showcases their expertise but also helps you understand how they tackle challenges specific to your industry. Lastly, ensure that they adhere to industry standards and certifications, which are crucial indicators of quality assurance in PCB assembly.

Importance of Local Support

Local support can make all the difference when dealing with complex electronics projects like those requiring one stop PCB assembly services. Having a nearby manufacturer means quicker communication and faster response times if issues arise during production or delivery. This proximity allows for easier collaboration throughout the project lifecycle, enhancing overall project management.

Additionally, local providers often offer personalized service that larger companies may lack, making it easier to address specific needs related to your unique project requirements. When searching for PCB assembly services near me, look for companies that emphasize their commitment to local partnerships and community engagement as this often reflects a higher level of customer care.

Evaluating Proximity and Service Range

When evaluating proximity and service range for your one stop PCB assembly needs, consider both distance and capability comprehensively. A provider might be close by but may not offer the full range of services required for your project—such as online PCB manufacturing or specialized SMT PCB Assembly Service options—which could necessitate working with multiple vendors.

It's also wise to assess their ability to scale operations based on your project size; some manufacturers excel at small runs while others are equipped for large-scale production without sacrificing quality or lead times. Ultimately, finding a balance between location convenience and comprehensive service offerings will streamline your supply chain while ensuring timely delivery of high-quality products.

The Benefits of SMT PCB Assembly Service

When it comes to modern electronics manufacturing, the advantages of SMT (Surface Mount Technology) PCB assembly service are hard to ignore. This method not only enhances the efficiency of production but also ensures a level of precision that traditional methods struggle to match. For businesses looking for one stop PCB assembly solutions, SMT offers a compelling combination of speed and accuracy that can elevate project outcomes significantly.

Superior Efficiency and Precision

SMT PCB assembly is renowned for its superior efficiency, largely due to its ability to accommodate high-density circuit designs in a compact space. By placing components directly onto the surface of the printed circuit board, manufacturers can reduce assembly time and increase throughput—an essential factor for any one stop PCB assembly manufacturer aiming for quick turnarounds. Additionally, the precision offered by SMT minimizes errors during placement, ensuring that each component functions optimally within the overall design.

How SMT Enhances Performance

The performance enhancement provided by SMT is a game changer in electronics manufacturing. By allowing for smaller components and tighter spacing, SMT enables more complex functionality within a reduced footprint—perfect for those seeking integrated one stop PCB assembly parts that don’t compromise on quality or performance. Moreover, this technology supports better thermal management and electrical performance across various applications, making it an ideal choice for cutting-edge electronic devices.

Case Studies of Successful Implementations

Several case studies illustrate how companies have thrived using SMT PCB assembly services as part of their production process. For instance, a leading tech firm integrated SMT into their product line and reported a 30% reduction in lead times while simultaneously increasing output quality—an impressive feat that underscores the value of finding reliable PCB assembly services near me or online. Another example is an automotive manufacturer who adopted this technology to enhance their vehicle control systems; they benefited from improved reliability and performance metrics across multiple models thanks to efficient one stop PCB assembly practices.

How to Get a PCB Assembly Quote

Getting a PCB assembly quote can feel like navigating a maze, especially with so many options available in the realm of one stop PCB assembly. However, understanding the key factors that influence pricing can help streamline this process. By focusing on essential elements and employing smart comparison strategies, you’ll be well-equipped to find the best deal for your project.

Understanding Pricing Factors

When seeking a PCB assembly quote, several pricing factors come into play that you should be aware of. First, the complexity of your design significantly impacts cost; intricate layouts or high-density components typically require more labor and time. Additionally, the choice between one stop PCB assembly parts versus traditional sourcing can affect overall expenses due to potential savings in shipping and handling.

Another critical factor is the volume of production—bulk orders generally yield lower per-unit costs compared to small runs. The materials used also contribute to pricing; opting for high-quality components may raise initial costs but can lead to better performance and longevity in your final product. Finally, don’t overlook hidden fees such as setup charges or expedited service costs that could sneak up on you if not accounted for upfront.

Essential Elements to Consider

When requesting a PCB assembly quote, there are several essential elements you should consider to ensure you're making an informed decision. Start with clear specifications about your project—this includes details like board dimensions, layer count, and component types needed for SMT PCB assembly service or through-hole technology. Providing precise information will help manufacturers give accurate quotes tailored specifically to your needs.

Next up is turnaround time; some projects may require faster delivery than others. Make sure you communicate any deadlines clearly so that potential providers can accommodate them in their quotes without compromising quality or service levels. Lastly, inquire about warranty terms and support services offered by one stop PCB assembly manufacturers—this could save you headaches down the line if issues arise post-assembly.

Tips for Comparison Shopping

Comparison shopping for PCB assembly services near me doesn’t have to be daunting if approached strategically! Start by gathering multiple quotes from various providers specializing in one stop PCB assembly; this allows you to see where prices vary significantly and why they do so based on their offerings and capabilities.

Look beyond just cost when evaluating these quotes—consider factors such as lead times, customer reviews, previous case studies (especially those involving SMT PCB Assembly Service), and overall reputation within the industry. A slightly higher price might be worth it if it means working with a reliable partner known for exceptional quality assurance in their processes.

Lastly, leverage online tools for quick comparisons; many online platforms provide side-by-side evaluations of different manufacturers’ services including shipping times and customer support options. This not only saves time but also ensures you're choosing a solution that fits both your budgetary constraints and project requirements seamlessly.

Conclusion

In the fast-paced world of electronics, the need for efficient and reliable solutions is paramount. One stop PCB assembly simplifies your electronics projects by consolidating various services into one cohesive package. This streamlined approach not only saves time but also enhances overall project management, allowing you to focus on innovation rather than logistics.

Simplifying Your Electronics Projects

Navigating the complexities of electronics manufacturing can be daunting, but one stop PCB assembly makes it easier than ever. By integrating multiple services—such as design, prototyping, and production—into a single provider, you eliminate the headaches associated with coordinating different suppliers. This simplification leads to smoother workflows and reduces the potential for miscommunication or delays.

The Competitive Edge of Integrated Services

The advantages of using integrated services like one stop PCB assembly are clear: efficiency, cost savings, and enhanced collaboration among teams. When all components are sourced from one place, you benefit from a streamlined supply chain that minimizes lead times and optimizes resource allocation. As competition in the electronics industry intensifies, leveraging these integrated solutions can provide a crucial edge over rivals who may still rely on fragmented processes.

Why You Should Choose Bensun Technology

When searching for quality PCB assembly services near me, Bensun Technology stands out as a top choice among one stop PCB assembly manufacturers. Their commitment to quality assurance ensures that every product meets rigorous standards while offering adaptable services tailored to your specific needs. With their expertise in SMT PCB Assembly Service and competitive pricing structures for PCB assembly quotes, choosing Bensun Technology means investing in reliability and excellence.