Introduction

Understanding the Pick & Place Machine

A pick & place machine is an automated device designed to handle the complex task of placing electronic components on PCBs. This sophisticated equipment uses advanced algorithms and high-speed robotics to ensure that each component is positioned accurately, reducing human error and increasing production rates. From desktop pick and place machines suited for small-scale operations to larger automatic pick and place machines for industrial use, these devices have revolutionized PCB assembly.

The Importance of PCB Assembly

PCB assembly is a vital step in the electronics manufacturing process; it transforms raw materials into functional devices we rely on daily. The precision involved in this process ensures that electronic products perform optimally, which is crucial for everything from smartphones to medical equipment. With advancements in SMT (Surface Mount Technology) and efficient pick & place solutions, manufacturers can achieve higher quality standards while meeting increasing market demands.

Overview of SMT Technology

SMT technology represents a significant leap forward in PCB assembly techniques by allowing components to be mounted directly onto the surface of PCBs rather than through holes. This method not only saves space but also enhances performance by improving electrical connectivity and reducing signal interference. By integrating SMT with modern pick & place machines, manufacturers can streamline their processes, reduce costs associated with labor-intensive manual assembly, and ultimately drive innovation across various industries.

What is a Pick & Place Machine

In the world of electronics manufacturing, the pick & place machine stands out as a vital tool for assembling printed circuit boards (PCBs). This sophisticated device automates the process of placing electronic components onto PCBs with remarkable precision and speed. Whether you're a hobbyist or running a startup, understanding what a pick & place machine can do is essential for optimizing your PCB assembly process.

Definition and Functionality

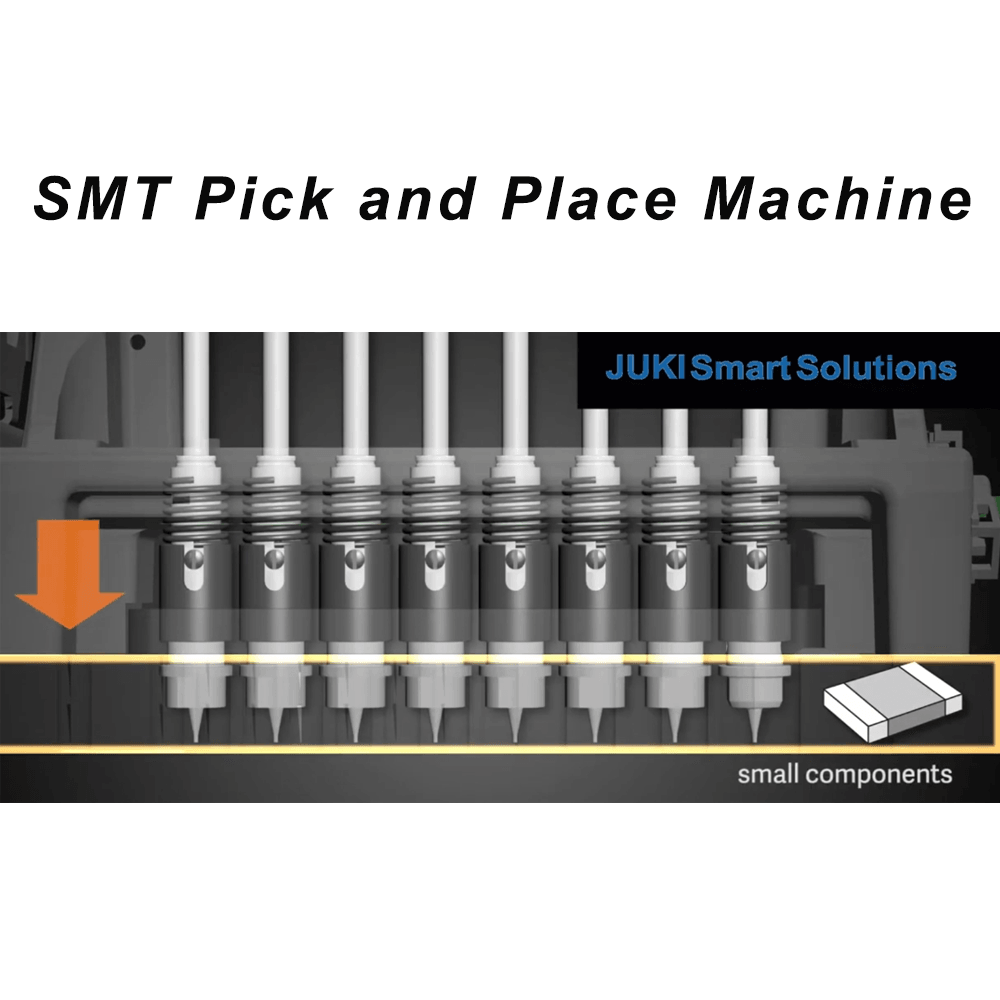

A pick & place machine is an automated system designed to accurately position electronic components on PCBs during assembly. These machines utilize advanced technology to pick components from feeders and place them at designated locations on the board. The functionality of these machines varies, but they typically include features like vision systems for alignment and programmable settings for different PCB layouts.

How it Works in PCB Assembly

The operation of a pick & place machine in PCB assembly is both fascinating and intricate. First, the machine identifies the required components through its vision system or pre-programmed data. Once identified, it uses robotic arms to pick up each component from its feeder and precisely place it onto the PCB. This automation not only speeds up production but also significantly reduces human error, making it an essential tool in modern electronics manufacturing.

Types of Pick & Place Machines

When diving into the realm of pick & place machines, you'll find various types tailored to different needs and production scales. Desktop pick and place machines are perfect for small-scale operations or hobbyists looking to assemble their own projects efficiently. On the other hand, industrial models offer higher throughput and capabilities suitable for large-scale manufacturing environments. Each type has its own unique features that cater to specific market demands, making it crucial to choose wisely based on your operational needs.

The Role of a Desktop Pick and Place Machine

In the realm of PCB assembly, the desktop pick and place machine has carved out a niche that caters specifically to small-scale operations. This compact marvel not only streamlines the assembly process but also offers an array of advantages for businesses that do not require the massive output capabilities of industrial models. With its growing popularity, understanding its role is essential for hobbyists, startups, and even established companies looking to optimize their production lines.

Advantages for Small Production Runs

One of the standout features of a desktop pick and place machine is its suitability for small production runs. Unlike their larger counterparts, these machines are designed to handle low-volume manufacturing efficiently without sacrificing quality or precision. This means that companies can produce PCBs in smaller batches while minimizing waste and reducing costs associated with larger setups—essentially making every penny count when it comes to pick & place machine price.

Moreover, desktop models often come equipped with user-friendly interfaces that allow operators to quickly set up jobs without extensive training or experience. This ease of use is crucial in environments where time is money; businesses can pivot quickly between projects without needing specialized staff. Ultimately, this flexibility makes desktop pick and place machines an attractive option for those looking to maximize productivity in small-scale operations.

Ideal for Hobbyists and Startups

For hobbyists and startups venturing into PCB design and assembly, a desktop pick and place machine can be a game changer. These machines provide an accessible entry point into SMT technology without requiring hefty investments typical of industrial equipment. As budding entrepreneurs experiment with new designs or products, having a reliable pick & place solution at their disposal allows them to bring ideas from concept to reality more rapidly.

Additionally, many hobbyists appreciate the compact size of these machines as they often operate from home workshops or shared spaces where real estate is limited. The ability to perform automatic pick and place functions significantly reduces manual labor involved in assembly—freeing up valuable time that can be spent on innovation rather than repetitive tasks. This combination of affordability, space efficiency, and functionality makes desktop models particularly appealing for those just starting out.

Comparing Desktop vs. Industrial Models

Industrial models are generally built for high-speed production with advanced automation features capable of handling thousands of components per hour—ideal for large manufacturers focused on mass production runs but not always feasible for smaller operations due to their higher costs.

On the other hand, while desktop machines may lack some high-end capabilities found in industrial variants, they excel in versatility and ease-of-use—making them perfect companions for smaller firms or individual creators who require precise placement without extensive overhead costs associated with larger setups like those seen among leading pick & place machine manufacturers. By understanding these distinctions clearly, users can make informed decisions tailored specifically toward their production needs while keeping an eye on overall efficiency.

Key Features of SMT Pick and Place Machines

Precision and Speed in Assembly

One of the standout characteristics of SMT pick and place machines is their unmatched precision and speed during assembly. These machines utilize advanced robotics to position components with incredible accuracy, reducing the risk of errors that can occur in manual assembly processes. The result? Faster production times without sacrificing quality—an essential factor for any business looking to scale operations efficiently.

Moreover, the speed at which a pick & place machine operates allows manufacturers to meet tight deadlines while maintaining high standards. Whether you're assembling complex PCBs or simple designs, having a reliable machine ensures that each component is placed accurately on the board every time. This combination of precision and speed makes investing in a quality pick & place machine price worthwhile for both hobbyists and professional manufacturers alike.

Compatibility with Various PCB Sizes

Another significant advantage of SMT pick and place machines is their compatibility with various PCB sizes. Many models are designed to handle everything from small prototype boards to larger production runs without compromising performance or requiring extensive adjustments. This flexibility allows businesses to adapt quickly to changing project requirements without investing in multiple machines.

For those using desktop pick and place machines, this feature becomes even more critical as it enables hobbyists or startups to experiment with different designs without facing limitations imposed by equipment size constraints. Additionally, the ability to work with various PCB sizes helps streamline operations by reducing downtime associated with setup changes between different projects. Ultimately, compatibility ensures that your investment in a pick & place machine delivers long-term value across diverse applications.

Advanced Software for Easy Operation

The integration of advanced software into SMT pick and place machines revolutionizes how users interact with these technologies. Modern systems often come equipped with user-friendly interfaces that simplify programming tasks—no need for extensive training or technical expertise! With intuitive controls, even newcomers can quickly learn how to operate a desktop pick and place machine effectively.

Furthermore, many automatic pick and place machines feature software that allows for real-time monitoring of the assembly process, providing insights into performance metrics such as placement accuracy or cycle times. This data can be invaluable for optimizing workflows over time while ensuring consistent quality across all assemblies produced on your PCB line. In short, advanced software not only enhances ease of use but also empowers manufacturers to achieve greater efficiency through data-driven decision-making.

Pick & Place Machine Price Factors

When considering a pick & place machine for your PCB assembly needs, price is often a pivotal factor. The cost of these machines can vary widely based on several elements, including their capabilities and the specific features they offer. Understanding the nuances of pick & place machine pricing will help you make an informed decision, whether you're looking at a desktop pick and place machine for hobby projects or an automatic pick and place machine for larger-scale production.

Initial Investment vs. Long-term Savings

The initial investment in a pick & place machine can be daunting, especially for startups and hobbyists. However, it’s essential to weigh this upfront cost against long-term savings that come from increased efficiency and reduced labor costs in PCB assembly. A quality SMT pick and place machine may require more capital initially but can significantly cut down on production time and errors over its lifespan.

Investing in a desktop pick and place machine might seem like a budget-friendly option at first glance, but if you plan to scale up your operations, it could lead to higher costs down the line due to slower assembly speeds or limited capabilities. Conversely, choosing an automatic pick and place machine with advanced features could mean higher upfront costs but ultimately provide better value through faster turnarounds and improved accuracy. Thus, understanding your production needs will guide you toward the best financial decision.

Cost Comparison Among Leading Brands

When diving into the world of pick & place machines, it's beneficial to conduct a thorough cost comparison among leading brands in the market. Different manufacturers offer varying price points depending on their technology advancements and support services provided with their machines. For instance, while some brands may charge less for their desktop models, others might justify higher prices with superior build quality or additional features tailored for complex PCB designs.

Brands like Bensun Technology have made waves in the industry by balancing affordability with high performance in their SMT pick and place machines. On the other hand, established names may come with premium pricing due to brand reputation but can also deliver exceptional reliability that justifies the investment over time. Therefore, assessing both initial costs as well as potential operating expenses is crucial when comparing options.

Essential Features That Affect Pricing

Several essential features influence the pricing of pick & place machines beyond just brand reputation or model type; these include precision levels, speed of operation, software compatibility, and adaptability to different PCB sizes. For example, advanced vision systems that enhance placement accuracy tend to increase the price tag but are invaluable for high-quality assemblies where precision is non-negotiable.

Moreover, flexibility in handling various component types can also impact pricing; machines capable of placing both large components as well as tiny surface mount devices (SMDs) generally command higher prices due to their versatility in diverse manufacturing environments. Finally, user-friendly software that simplifies operation not only enhances productivity but often comes at a premium—making it an important consideration when evaluating overall value versus cost in your desired pick & place solution.

Leading Pick and Place Machine Manufacturers

In the ever-evolving landscape of PCB assembly, the choice of a reliable pick & place machine manufacturer can significantly influence production efficiency and quality. Among the myriad options available, Bensun Technology stands out for its commitment to innovation and customer satisfaction. This section will explore Bensun's offerings, highlight other noteworthy manufacturers in the industry, and discuss what makes Bensun a preferred choice.

A Look at Bensun Technology

Bensun Technology has carved a niche for itself in the realm of SMT pick and place machines with its focus on precision engineering and user-friendly designs. Their desktop pick and place machines are particularly popular among hobbyists and small businesses looking for efficient solutions without breaking the bank. With an emphasis on affordability, Bensun offers competitive pick & place machine prices while maintaining high-quality standards.

One of their flagship products is the automatic pick and place machine, which combines speed with accuracy to handle various PCB sizes seamlessly. This versatility makes it an invaluable tool for both prototyping and small-scale production runs. Additionally, Bensun's commitment to after-sales support ensures that customers can maximize their investment in SMT technology.

Other Notable Industry Players

While Bensun Technology shines brightly in this space, several other notable manufacturers also contribute significantly to the market for pick & place machines. Companies like Panasonic, Juki, and Yamaha have established themselves as leaders by offering a range of models tailored for different production needs—from high-volume industrial setups to more compact desktop solutions.

These manufacturers often focus on advanced automation features that enhance productivity while minimizing errors during assembly. Their SMT pick and place machines are designed with state-of-the-art technology that supports quick changeovers between different PCB types—an essential feature for companies looking to maximize efficiency on diverse projects. As competition heats up among these players, consumers can expect continuous improvements in performance at varying price points.

What Sets Bensun Apart from Competitors

What truly sets Bensun apart from other pick & place machine manufacturers is its unique blend of accessibility, innovation, and customer-centric design philosophy. While competitors may offer robust features at higher price points, Bensun’s desktop pick and place machines provide similar capabilities without overwhelming budget constraints—making them ideal for startups or hobbyists venturing into PCB assembly.

Moreover, their user-friendly software interface simplifies operation even for those new to SMT technology; this ease of use is often cited as a key reason customers choose their products over others in the market. Finally, Bensun’s dedication to continuous improvement means they actively seek feedback from users to refine their offerings further—a practice that fosters loyalty among existing clients while attracting new ones seeking reliable solutions at reasonable prices.

Conclusion

In the realm of PCB manufacturing, selecting the right pick & place machine is crucial for achieving optimal efficiency and quality. With a wide variety of options available, from desktop pick and place machines to more advanced automatic pick and place machines, understanding your specific needs is essential. Consider factors such as production volume, budget constraints, and the types of components you’ll be working with to make an informed decision.

Choosing the Right Pick & Place Solution

When it comes to choosing a pick & place solution, it's important to weigh your options carefully. For hobbyists or startups focusing on small production runs, a desktop pick and place machine can offer flexibility without breaking the bank. However, if you're aiming for larger-scale operations or higher precision in assembly, investing in an industrial SMT pick and place machine may be worth considering despite its higher price tag.

The Future of PCB Manufacturing

The future of PCB manufacturing looks bright with advancements in technology driving innovation in pick & place machines. As manufacturers strive for greater efficiency and precision, we can expect even more sophisticated features in SMT pick and place machines that cater to diverse production needs. Moreover, as automation continues to take center stage, automatic pick and place machines will become increasingly vital for maintaining competitive edge in the ever-evolving electronics market.

Final Thoughts on SMT Technology and Efficiency

In conclusion, SMT technology is revolutionizing how we approach PCB assembly by enhancing speed and accuracy through advanced machinery like the pick & place machine. As competition intensifies within the industry, understanding the nuances between various models—whether it’s a desktop variant or an industrial-grade option—will empower businesses to optimize their processes effectively. Ultimately, embracing these technologies not only improves productivity but also sets the stage for future innovations in electronic manufacturing.