Introduction

In the ever-evolving world of electronics, the PCB SMT assembly machine stands as a pivotal player in manufacturing efficiency and precision. These machines are designed to streamline the process of assembling surface mount technology (SMT) components onto printed circuit boards (PCBs). Understanding what these machines do and their significance in PCB production is crucial for anyone involved in electronics manufacturing.

Understanding PCB SMT Assembly Machines

PCB SMT assembly machines are specialized equipment used to place electronic components on PCBs during the manufacturing process. They employ advanced technology to ensure that components are accurately positioned, soldered, and tested, which is essential for producing high-quality electronic devices. By integrating various functions into a single system, these machines enhance productivity while minimizing human error.

The Importance of SMT in PCB Production

The importance of SMT in PCB production cannot be overstated; it has revolutionized how electronic devices are assembled. SMT allows for smaller components to be placed closer together on a board, leading to more compact designs and improved performance. This capability has made it possible to produce everything from smartphones to medical devices with greater efficiency and reliability.

Key Players in the SMT Machine Market

In the competitive landscape of PCB SMT assembly machine manufacturers, several key players dominate the market with their innovative solutions and reliable performance. Companies like Bensun Technology have emerged as significant contributors, offering unique features that cater to diverse industry needs. Understanding who these players are can help businesses make informed decisions when investing in SMT technology.

What is SMT PCB Assembly?

SMT (Surface Mount Technology) PCB assembly is a process that revolutionizes how electronic components are attached to printed circuit boards (PCBs). This technique allows for the placement of components directly onto the surface of the board, leading to more compact and efficient designs. Understanding what SMT PCB assembly entails is essential for anyone involved in electronics manufacturing.

Definition and Process Overview

At its core, SMT PCB assembly refers to the method of mounting electronic components directly onto the surface of a PCB rather than through holes as seen in traditional methods. The process typically begins with applying solder paste to designated areas on the board, followed by placing components using a pcb smt assembly machine. After placement, the board goes through a reflow oven where heat melts the solder, securing the components in place.

The efficiency and speed provided by modern pcb smt assembly machines streamline production lines significantly compared to older technologies. Additionally, these machines can handle various component sizes and types with high precision, making them versatile tools in electronics manufacturing. This overview highlights how crucial understanding SMT processes is when considering what is SMT PCB assembly.

Advantages of SMT in Electronics

The advantages of using SMT in electronics are numerous and impactful. For one, it allows for higher component density on PCBs; this means more functionality can be packed into smaller devices—a key factor as consumer demands for compact gadgets increase. Furthermore, because components are mounted directly on surfaces rather than through holes, manufacturers can achieve better performance due to reduced inductance and capacitance.

Another significant benefit is improved reliability; solder joints formed during reflow are generally stronger than those made with earlier methods like through-hole technology. Additionally, automation capabilities mean that production rates soar while reducing human error—something that’s hard to beat when discussing what is the machine used in SMT! Overall, these advantages make it clear why many industries are leaning toward pcb smt assembly machines for their production needs.

Common Applications in Industry

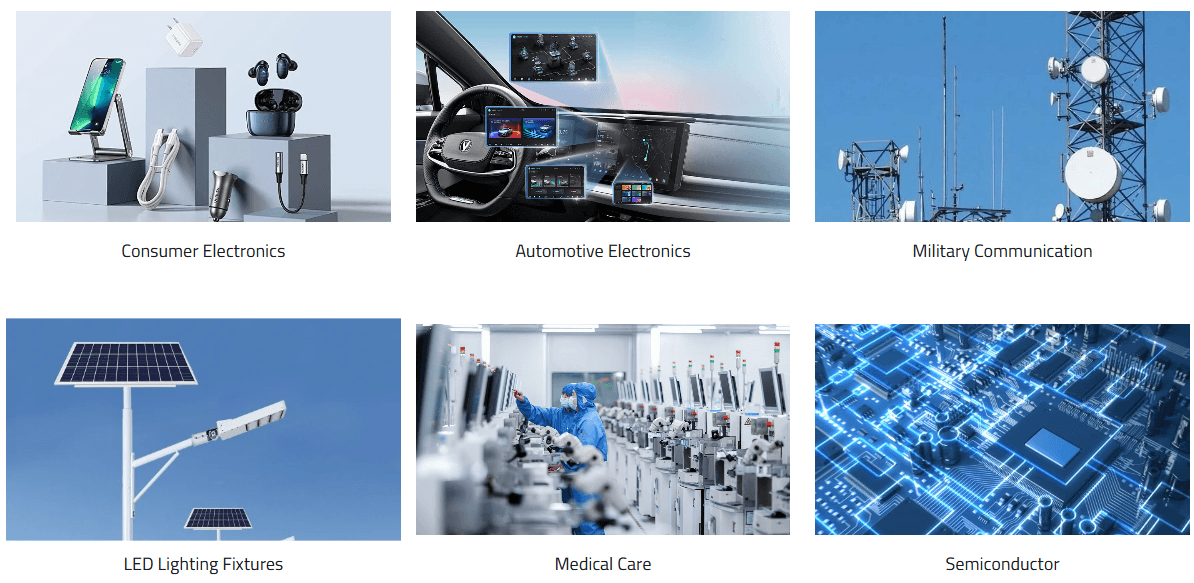

SMT PCB assembly finds its way into numerous industries due to its versatility and efficiency. Common applications include consumer electronics like smartphones and tablets where space-saving designs are paramount. Other sectors benefiting from this technology include automotive systems that require reliable performance under extreme conditions and medical devices where precision is critical.

In telecommunications equipment, SMT enables manufacturers to create smaller yet powerful devices capable of handling vast amounts of data traffic efficiently—essentially driving innovation forward! The flexibility offered by modern pcb smt assembly machines also allows companies to adapt quickly to changing market demands without sacrificing quality or speed. With such widespread applications across various fields, it’s evident why understanding what is SMT PCB assembly holds significant importance today.

What is the Machine Used in SMT?

When diving into the world of PCB SMT assembly machines, one must appreciate the intricacies of the technology that makes it all possible. These machines are essential for modern electronics manufacturing, providing speed, precision, and efficiency. Understanding what constitutes these machines helps demystify their role in producing high-quality printed circuit boards (PCBs).

Key Components of SMT Machines

At the heart of any PCB SMT assembly machine lies several critical components that work in harmony to ensure seamless operation. These include a solder paste printer for applying solder paste accurately onto PCBs, placement machines that position surface mount components with pinpoint accuracy, and reflow ovens that melt solder to create strong electrical connections. Additional components like inspection systems and conveyor belts contribute to a fully integrated production line geared towards efficiency.

Moreover, each component plays a vital role in enhancing the overall performance of SMT processes. The combination of these elements ensures that manufacturers can achieve high throughput while maintaining quality standards. As such, understanding these key components is crucial for anyone interested in what is SMT PCB assembly?

Types of SMT Machines Explained

SMT machines come in various types tailored to specific needs within the PCB manufacturing process. The most common types include pick-and-place machines which are vital for component placement; solder paste printers which ensure proper solder application; and reflow ovens that finalize connections through heat application. Each type serves a distinct purpose but collectively contributes to efficient production.

Additionally, there are variations within each category based on functionality and scale – from semi-automatic models suited for smaller operations to fully automated systems designed for high-volume production lines. Understanding these differences helps manufacturers choose the right equipment based on their operational requirements and budget constraints related to pcb smt assembly machine price.

How Machines Integrate in Production Lines

The integration of PCB SMT assembly machines into production lines is where magic truly happens; it's all about synergy and workflow optimization! These machines are designed to work together seamlessly, allowing for continuous movement from one stage of production to another without bottlenecks or delays. For instance, once a solder paste printer applies its magic on a PCB, it moves directly to the placement machine without manual intervention.

This streamlined process not only enhances productivity but also minimizes human error—an essential factor when considering what is the difference between PCB and PCB assembly? Moreover, integrating advanced technologies like AI-driven inspection systems can further refine quality control throughout this intricate dance of machinery. Ultimately, understanding how these machines fit within larger operations provides insights into choosing top-tier pcb smt assembly machine manufacturers who can deliver reliable solutions.

What is the Top 10 Popular SMT Machine Brands?

Overview of Leading Brands

The SMT machine market is home to several leading brands that have carved out their niches through innovation and quality. Companies like Yamaha, Panasonic, and Juki have long been recognized for their advanced technology and dependable machines. These brands not only provide high-speed solutions for PCB SMT assembly but also ensure precision and efficiency in the manufacturing process.

In addition to these giants, newer players like Bensun Technology are making waves by offering competitive alternatives that often come with unique features tailored for specific applications. By understanding what each brand brings to the table, manufacturers can make informed decisions about which PCB SMT assembly machine best suits their operational requirements. Ultimately, choosing from the top 10 popular SMT machine brands can lead to enhanced production capabilities and improved product quality.

Bensun Technology’s Unique Offerings

Bensun Technology has emerged as a formidable player in the realm of PCB SMT assembly machines by focusing on customization and user-friendly interfaces. Their machines are designed with versatility in mind, catering to both small-scale operations and large-scale production lines alike. With an emphasis on cost-effectiveness without compromising quality, Bensun provides an attractive option for businesses looking to upgrade or expand their manufacturing capabilities.

What sets Bensun apart is its commitment to customer service; they offer comprehensive support throughout the purchasing process and beyond. This includes training on how to operate their machines effectively within existing production lines—an essential factor when considering what is the machine used in SMT? By blending advanced technology with exceptional service, Bensun Technology positions itself as a strong contender among popular SMT machine brands.

Brand Performance and Reliability

When evaluating which brands rank among the top 10 popular SMT machine manufacturers, performance metrics such as speed, accuracy, and uptime play key roles in determining reliability. Leading brands consistently receive high marks for their durability under demanding conditions—a crucial aspect when considering PCB smt assembly machine price versus value delivered over time.

Moreover, customer reviews often highlight how well these machines integrate into existing workflows; this reflects positively on brand performance overall. As companies weigh options between different PCB SMT assembly machines available on the market today, understanding each brand's reputation for reliability becomes imperative for long-term success.

What is the Difference Between PCB and PCB Assembly?

In the world of electronics manufacturing, understanding the distinction between PCB and PCB assembly is crucial. A printed circuit board (PCB) serves as a foundational component that provides mechanical support and electrical connections for electronic components. On the other hand, PCB assembly refers to the process of placing these components onto the PCB to create a functional electronic circuit. This difference is not just semantic; it has significant implications for production processes and efficiency.

Defining PCB and PCB Assembly

A printed circuit board (PCB) is essentially a flat board made from insulating material with conductive pathways etched or printed onto its surface. These pathways allow for electrical connections between various electronic components, such as resistors, capacitors, and integrated circuits. Conversely, PCB assembly involves soldering these components onto the prepared PCBs using techniques like surface mount technology (SMT), which utilizes specialized machines known as pcb smt assembly machines to automate this process.

Importance of Understanding the Distinction

Recognizing the difference between a bare PCB and its assembled counterpart can greatly influence decision-making in manufacturing processes. For instance, if one mistakenly conflates PCBs with their assemblies, it may lead to miscalculations in cost estimations or project timelines when investing in pcb smt assembly machine capabilities or selecting appropriate manufacturers. Additionally, this understanding helps stakeholders communicate more effectively about product specifications and requirements throughout production stages.

Impact on Production Efficiency

The distinction between PCBs and their assemblies directly affects production efficiency by influencing workflow strategies and resource allocation. For example, knowing that pcb smt assembly machines are specifically designed for assembling components rather than producing PCBs allows manufacturers to optimize their operations by investing in both types of equipment appropriately. This clarity can lead to streamlined processes that enhance overall productivity while ensuring quality standards are met across different production stages.

PCB SMT Assembly Machine Price Factors

When it comes to purchasing a PCB SMT assembly machine, understanding the price factors is crucial for making an informed decision. The cost of these machines can vary significantly based on several variables, including type, features, and manufacturer reputation. Knowing what influences these prices will help buyers navigate the market effectively.

Price Ranges for Different Machines

The price of a PCB SMT assembly machine can range from a few thousand dollars for entry-level models to over a million dollars for high-end, fully automated systems. Entry-level machines are typically suitable for small-scale operations or prototyping, while advanced machines cater to large manufacturers requiring high-speed production capabilities. It's essential to consider your production volume and specific needs when evaluating which price range is appropriate.

Impact of Features on Cost

Features play a significant role in determining the price of PCB SMT assembly machines. For instance, machines equipped with advanced technology such as automatic optical inspection (AOI), integrated pick-and-place systems, and flexible feeding options tend to be more expensive than basic models lacking these functionalities. Buyers must weigh their need for features against their budget; investing in more advanced capabilities can lead to greater efficiency and reduced long-term costs.

Cost vs. Quality Considerations

Choosing between cost and quality is often a dilemma faced by businesses in need of a PCB SMT assembly machine. While lower-priced options may seem attractive initially, they could lead to higher maintenance costs or lower production efficiency over time. It’s vital to assess not only the upfront price but also the long-term value that quality machinery brings—after all, investing in reliable equipment can significantly enhance overall productivity and reduce downtime.

Top PCB SMT Assembly Machine Manufacturers

The world of PCB SMT assembly machines is vast, with numerous manufacturers vying for attention in this competitive market. As the demand for efficient and high-quality production processes increases, leading manufacturers are stepping up to provide innovative solutions that cater to a range of industry needs. Understanding who these key players are can help businesses make informed decisions when investing in their PCB SMT assembly machine.

Overview of Leading Manufacturers

When exploring the landscape of PCB SMT assembly machine manufacturers, several names consistently emerge at the top. Companies such as ASM Pacific Technology, Panasonic, and Juki have established themselves as leaders due to their commitment to innovation and quality. These manufacturers offer a variety of machines designed for different applications within SMT PCB assembly, ensuring that businesses can find the right fit for their production lines.

Additionally, brands like Yamaha and Mydata are known for their advanced technology and user-friendly interfaces, making them popular choices among electronics manufacturers. With an array of options available, understanding what is offered by each manufacturer is crucial in determining which PCB SMT assembly machine aligns best with your operational goals.

Bensun Technology’s Market Position

Bensun Technology has carved out a significant niche within the realm of PCB SMT assembly machines. Known for its robust engineering and reliable performance, Bensun offers machines that meet various production demands while maintaining cost-effectiveness—a crucial factor in today’s competitive market landscape. Their focus on innovation allows them to stay ahead by integrating cutting-edge technology into their product offerings.

As a rising star among pcb smt assembly machine manufacturers, Bensun has garnered attention not just for its quality but also for exceptional customer service and support post-purchase. This combination has positioned them favorably against more established brands while appealing to both small-scale operations and larger enterprises looking to optimize their electronic manufacturing processes.

Evaluating Manufacturer Reputation

Reputation plays a vital role when selecting from the top pcb smt assembly machine manufacturers; it reflects reliability and customer satisfaction over time. Assessing reviews from existing users can provide valuable insights into how well each manufacturer supports its products throughout the lifecycle—from installation through maintenance—thereby influencing long-term operational efficiency.

Moreover, industry awards or certifications can serve as indicators of quality assurance within these companies’ practices—a key consideration when pondering what is the best choice among available options in the market today. Ultimately, understanding these reputational factors will guide businesses toward making informed decisions regarding which pcb smt assembly machine will best suit their unique production requirements.

Conclusion

The world of PCB SMT assembly machines is both intricate and essential for modern electronics manufacturing. Understanding the nuances of what is SMT PCB assembly? and the machines used in this process can greatly enhance production efficiency and quality. As we wrap up, let’s reflect on the key takeaways, the market landscape, and what lies ahead for this dynamic industry.

Key Takeaways on SMT Assembly Machines

SMT assembly machines have revolutionized how PCBs are produced, allowing for faster and more reliable manufacturing processes. The key components of these machines include pick-and-place systems, solder paste printers, and reflow ovens, all working in harmony to create high-quality electronic products. Additionally, knowing what is the top 10 popular SMT machine brands can guide manufacturers in selecting reliable equipment that meets their specific needs.

Understanding the Market Landscape

The market for PCB SMT assembly machines is diverse and competitive, with numerous manufacturers vying for attention. Companies like Bensun Technology stand out due to their innovative offerings that cater to various industry demands. Understanding the difference between PCB and PCB assembly is crucial as it not only affects design choices but also influences purchasing decisions regarding machinery and materials.

The Future of PCB SMT Technology

Looking ahead, the future of PCB SMT technology appears promising with advancements in automation and artificial intelligence shaping production lines. As manufacturers strive to deliver higher quality products at lower costs, factors such as pcb smt assembly machine price will continue to evolve alongside technological innovations. Moreover, staying informed about top pcb smt assembly machine manufacturers will be essential for companies aiming to maintain a competitive edge in an ever-changing landscape.

[Image description=modern factory setting with advanced pcb smt assembly machine in operation, workers monitoring processes on screens], Image name=pcb_smt_assembly_machine_factory_setting, Alt tag=advanced pcb smt assembly machine in a modern factory setting